|

|

Автор: Williams Автор: Williams

Дата: 26 декабря 2022 Дата: 26 декабря 2022

Просмотров: 1 187 Просмотров: 1 187 |

| |

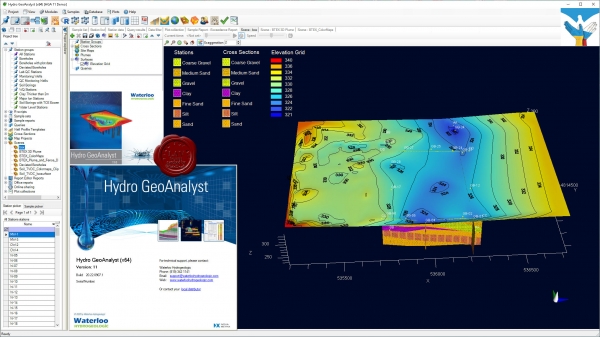

Schlumberger Hydro GeoAnalyst 11 build 20.22.0907.1

Schlumberger Hydro GeoAnalyst - комплексное программное решение для анализа данных и управления эксплуатацией подземных скважин.

Hydro GeoAnalyst is an environmental data management software that integrates a complete suite of analysis, visualization and reporting tools, with a powerful and flexible database. |

| |

Читать статью дальше (комментариев - 14)

Читать статью дальше (комментариев - 14)

| |

|

|

Автор: Williams Автор: Williams

Дата: 25 декабря 2022 Дата: 25 декабря 2022

Просмотров: 781 Просмотров: 781 |

| |

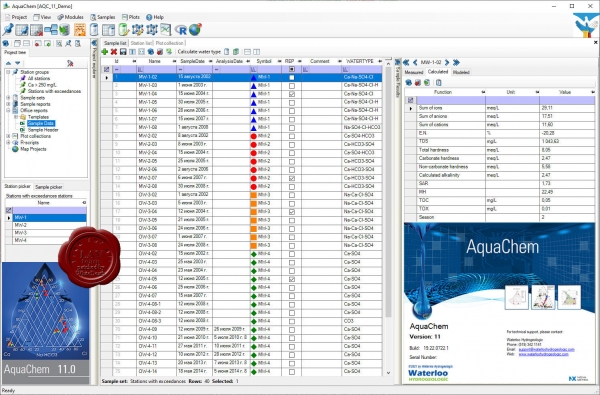

Schlumberger AquaChem 11 build 19.22.0722.1

Компания Schlumberger – одна из крупнейших нефтесервисных компаний в мире, предоставляющая весь спектр технологий и услуг для развития и поддержки инфраструктур нефтяной и газовой промышленности.

Schlumberger Water Services – одно из подразделений Schlumberger, специализирующееся на решении задач управления и эксплуатации водных ресурсов. Программное обеспечение, поставляемое Schlumberger Water Services, используется при моделировании движения подземных и поверхностных вод, управлении эксплуатацией подземных скважин, оценки качества подземных вод, построении карт и т. д. Программное обеспечение поставляется в виде отдельных модулей (Visual MODFLOW, Hydro GeoAnalyst, AquaChem, Aquifer Test Pro, GW Contour и т. д.), заточенных под решение узкоспециализированных задач.

Так вот, AquaChem - программный пакет для анализа и оценки качества подземных вод.

|

| |

Читать статью дальше (комментариев - 6)

Читать статью дальше (комментариев - 6)

| |

|

|

Автор: Williams Автор: Williams

Дата: 22 декабря 2022 Дата: 22 декабря 2022

Просмотров: 1 579 Просмотров: 1 579 |

| |

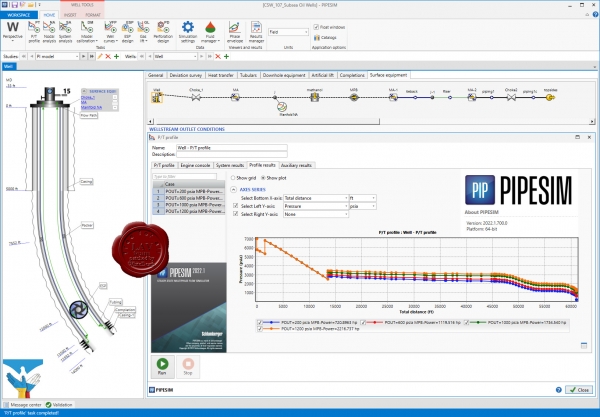

Schlumberger PIPESIM 2022.1.700 x64

Schlumberger PIPESIM обеспечивает моделирование установившегося многофазного потока для нефтегазодобывающих систем. Отдельные модули Schlumberger PIPESIM используются для большого числа аналитических исследований, таких как: моделирование скважины, оптимизация механизированной добычи, моделирование трубопроводов и технологического оборудования, планирование разработки месторождения. Schlumberger PIPESIM - набор модулей моделирования с применением передовых средств для разработки, проектирования и эксплуатации скважин, трубопроводов, промысловых объектов и сетей. Модули интегрированы таким образом, чтобы можно было построить полную модель системы добычи, начиная с месторождения и заканчивая центральным пунктом сбора, со специальными модулями по оптимизации работ в масштабе всего месторождения и по планированию разработки месторождения. Schlumberger PIPESIM является частью решения по интегрированному моделированию месторождений Avocet Integrated Asset Modeler (Avocet IAM), позволяющего интегрировать модели залежи, скважин и промыслового оборудования, систему сбора, подготовки, переработки и финансово-экономическую модель в единую систему управления добывающим активом.

Основные спецификации:

- моделирование многофазного стационарного течения;

- быстрые концептуальные исследования;

- расчет трубопроводов и технологического оборудования;

- расчет необходимого диаметра трубопровода;

- исследования чувствительности модели и ее оптимизация;

- обеспечение потока из высокоточных термогидравлических моделей;

- анализ режима потока, условий появления гидродинамических пробок и последствий очистки скребком;

- расчет размеров оборудования;

- расчет характеристик изоляции;

- расчет моделей скважин, включенных в эту же модель.

Модели оборудования:

- - сепараторы;

- мультифазные насосы;

- компрессоры и детандеры;

- нагревающие и охлаждающие устройства;

- штуцеры.

Преимущества программного комплекса PIPESIM:

- моделирование сетей сбора различных флюидов, систем нагнетания, магистральных трубопроводов;

- моделирование скважин и расчет потерь давления и температуры по скважине;

- моделирование и расчет различных видов смесей, в том числе вязких и высоковязких нефтей;

- широкие возможности по автоматизации, используя технологию Open Link.

|

| |

Читать статью дальше (комментариев - 13)

Читать статью дальше (комментариев - 13)

| |

|

|

Автор: Williams Автор: Williams

Дата: 22 ноября 2022 Дата: 22 ноября 2022

Просмотров: 569 Просмотров: 569 |

| |

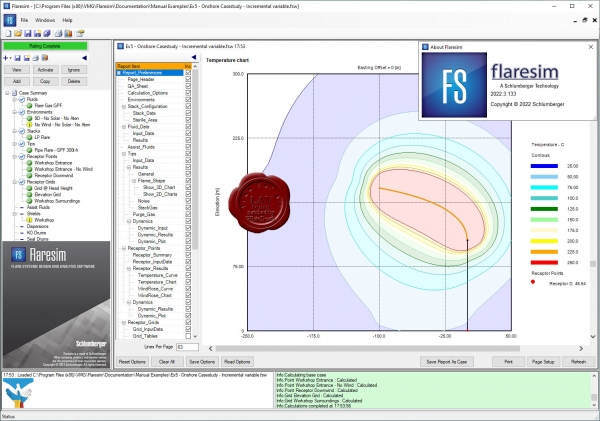

Schlumberger Flaresim 2022.3.133

Softbits is one of the leading specialist companies worldwide in the field of flare simulation. Based in Hampshire in the south of the UK, we develop and maintain Flaresim – the sophisticated, state-of-the-art, industry-standard flare design application for the oil, gas, liquefied natural gas (LNG) and refining industries.

Flaresim is our highly developed and sophisticated flare simulation/design application. Designed by professional engineers, for professional engineers, it models thermal radiation and noise footprints generated by flare systems for offshore platforms, gas plants, refineries and chemical plants, and predicts the temperature of exposed surfaces within range. The application can analyse installations of any complexity, with unlimited multiple flare tips on multiple vertical, horizontal or inclined flare stacks. Users can model pipe flares, sonic flares and liquid burners using a range of algorithms. They can also enter and report data in units of their choice, and can convert data to other units at any time.

Flaresim provides full 3D flame-shape analysis with complete flexibility in the location and orientation of multiple stacks, and rapid evaluation of flare systems under different wind speeds and directions. Shield options can be included. Working from the opposite perspective, Flaresim allows you to size stack or boom length to meet specific radiation, noise or surface-temperature limits at defined receptor points. Flaresim includes gas dispersion models for both jet dispersion of flammable gases close to the stack and Gaussian dispersion of pollutants at longer distances. The output from Flaresim is highly customisable, and you can select either summary or detailed output. Flaresim has a user-friendly interface and incorporates context-sensitive help at every stage for user guidance. |

| |

Читать статью дальше (комментариев - 5)

Читать статью дальше (комментариев - 5)

| |

|

|

Автор: Williams Автор: Williams

Дата: 12 ноября 2022 Дата: 12 ноября 2022

Просмотров: 647 Просмотров: 647 |

| |

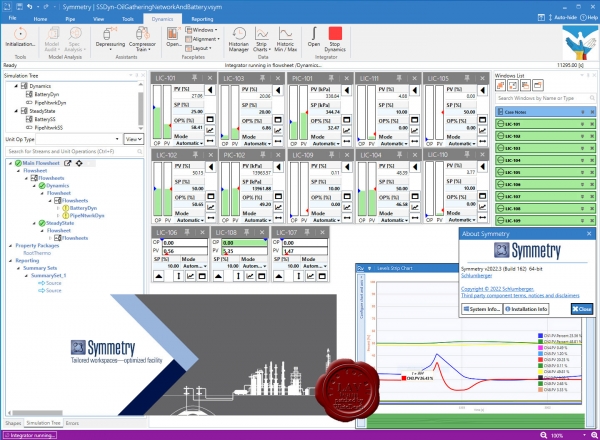

Schlumberger Symmetry 2022.3 build 162

Symmetry, a process software platform, is a comprehensive simulator that captures all aspects of your models from reservoir to product distribution. The Symmetry platform is built using VMG’s industry proven simulation technologies that have been optimized to scale to your engineering needs. The Symmetry platform uniquely integrates the modeling of fields, pipe networks, process plants and flare systems, providing an unprecedented level of collaboration. The Symmetry platform is designed with flexibility in mind. It can be used to model a specific application or to create a comprehensive model that may span from the field through different types of facilities. Everything using a consistent thermodynamic engine. If you are a VMGSim user you will feel right at home since the Symmetry platform builds upon familiar workflows and a powerful core of process simulation technology that comes from VMGSim.

Each flowsheet in a simulation model can be solved in steady state or dynamics, and different types of flowsheets provide tailored workspaces for models of processing facilities, pipe networks or flare systems. The steady state solver in the pipe and flare workspaces provides a unique combination of a pressure flow network solver and a sequential solver depending on the specifications. The Symmetry platform’s tailored workspaces include: VMGSim (World-class process simulation for facilities and plants); Pipe (Rigorous dynamic and steady-state multiphase modeling for complex pipe networks); Flare (All-inclusive relief system analysis with integrated PSV, network header and stack design); Field (Fully integrated gas reservoir and multiphase gathering system with forecasting functionality).

The VMGSim (Process), Pipe and Flare workspaces share the same process platform therefore they share the same extensive set of tools including regression, an optimizer, economics, connectivity and fluid characterization. The thermodynamic engine is consistent across the entire simulator and becomes a critical component of an integrated simulation model. Workspaces are tailored with specific features and views to promote common workflows and increase productivity. The flexible design of the Symmetry platform enables users to create simulations for a wide variety of applications and uses, from conceptual design to optimization and debottlenecking. The versatility of the Symmetry platform makes it the perfect tool for desktop work or for Industry 4.0 implementations.

|

| |

Читать статью дальше (комментариев - 7)

Читать статью дальше (комментариев - 7)

| |

|

|

Автор: Williams Автор: Williams

Дата: 4 ноября 2022 Дата: 4 ноября 2022

Просмотров: 717 Просмотров: 717 |

| |

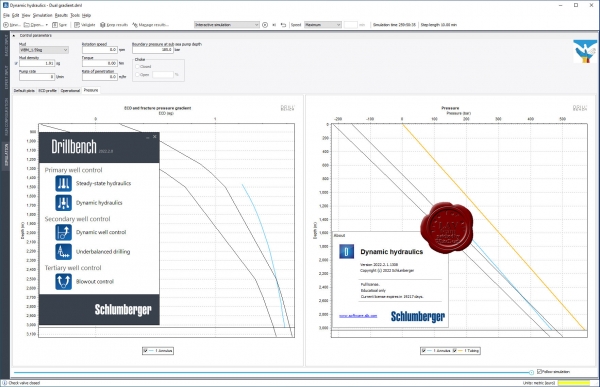

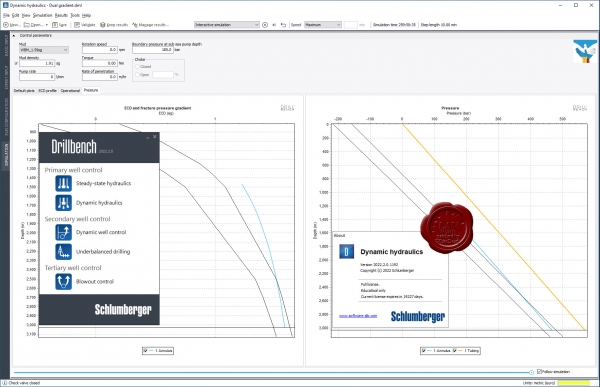

Schlumberger Drillbench 2022.2.1

Successfully drilling challenging wells requires an in-depth understanding of the hydraulics during all phases of the operation. The drilling process is highly dynamic and complicated to model; thus, much of the dynamics have traditionally been neglected. However, with diminishing operational margins, the impact of dynamic effects is growing. Coupled with increasing well construction costs, modeling the dynamics becomes essential and strategically important.

Dynamic simulations are a key feature to replicate a real drilling operation and provide accuracy not possible with simpler steady-state models. Drillbench software provides a user-friendly tool that targets all drilling engineers involved in challenging wells. The software is built around the well-control workflow, covering pressure control, well control, and blowout control. |

| |

Читать статью дальше (комментариев - 6)

Читать статью дальше (комментариев - 6)

| |

|

|

Автор: Williams Автор: Williams

Дата: 20 октября 2022 Дата: 20 октября 2022

Просмотров: 494 Просмотров: 494 |

| |

Schlumberger (ex. SPT Group) Drillbench 2022.2.0

Successfully drilling challenging wells requires an in-depth understanding of the hydraulics during all phases of the operation. The drilling process is highly dynamic and complicated to model; thus, much of the dynamics have traditionally been neglected. However, with diminishing operational margins, the impact of dynamic effects is growing. Coupled with increasing well construction costs, modeling the dynamics becomes essential and strategically important.

Dynamic simulations are a key feature to replicate a real drilling operation and provide accuracy not possible with simpler steady-state models. Drillbench software provides a user-friendly tool that targets all drilling engineers involved in challenging wells. The software is built around the well-control workflow, covering pressure control, well control, and blowout control. |

| |

Читать статью дальше (комментариев - 8)

Читать статью дальше (комментариев - 8)

| |

|

|

Автор: Williams Автор: Williams

Дата: 16 октября 2022 Дата: 16 октября 2022

Просмотров: 1 169 Просмотров: 1 169 |

| |

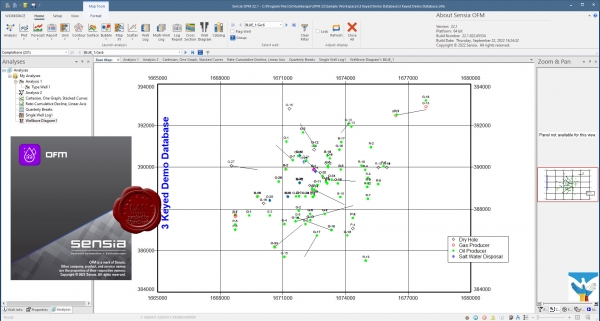

Schlumberger Sensia OFM 2022.1 build 922 x64

OFM is a powerful suite of modules developed by Schlumberger Information Solutions, designed to aid in the day-to-day surveillance and management of oil and gas fields. OFM provides an intuitive, user-friendly interface enabling you to view, enhance, and analyze production and reservoir data within the Microsoft Windows environment. Using OFM 2014, you can perform basic or complex analyses for individual or multiple completions, groups of wells, an entire field, or several fields. OFM is the ideal tool for reservoir production environments and users. It is ideally suited for the occasional user, yet sophisticated enough for the experienced geoscientist or petrophysicist, whether at the well site, office, or home. |

| |

Читать статью дальше (комментариев - 14)

Читать статью дальше (комментариев - 14)

| |

|

|

Автор: Williams Автор: Williams

Дата: 14 октября 2022 Дата: 14 октября 2022

Просмотров: 795 Просмотров: 795 |

| |

Schlumberger Symmetry 2022.2 build 149 x64

Symmetry, a process software platform, is a comprehensive simulator that captures all aspects of your models from reservoir to product distribution. The Symmetry platform is built using VMG’s industry proven simulation technologies that have been optimized to scale to your engineering needs. The Symmetry platform uniquely integrates the modeling of fields, pipe networks, process plants and flare systems, providing an unprecedented level of collaboration. The Symmetry platform is designed with flexibility in mind. It can be used to model a specific application or to create a comprehensive model that may span from the field through different types of facilities. Everything using a consistent thermodynamic engine. If you are a VMGSim user you will feel right at home since the Symmetry platform builds upon familiar workflows and a powerful core of process simulation technology that comes from VMGSim.

Each flowsheet in a simulation model can be solved in steady state or dynamics, and different types of flowsheets provide tailored workspaces for models of processing facilities, pipe networks or flare systems. The steady state solver in the pipe and flare workspaces provides a unique combination of a pressure flow network solver and a sequential solver depending on the specifications. The Symmetry platform’s tailored workspaces include: VMGSim (World-class process simulation for facilities and plants); Pipe (Rigorous dynamic and steady-state multiphase modeling for complex pipe networks); Flare (All-inclusive relief system analysis with integrated PSV, network header and stack design); Field (Fully integrated gas reservoir and multiphase gathering system with forecasting functionality).

The VMGSim (Process), Pipe and Flare workspaces share the same process platform therefore they share the same extensive set of tools including regression, an optimizer, economics, connectivity and fluid characterization. The thermodynamic engine is consistent across the entire simulator and becomes a critical component of an integrated simulation model. Workspaces are tailored with specific features and views to promote common workflows and increase productivity. The flexible design of the Symmetry platform enables users to create simulations for a wide variety of applications and uses, from conceptual design to optimization and debottlenecking. The versatility of the Symmetry platform makes it the perfect tool for desktop work or for Industry 4.0 implementations.

|

| |

Читать статью дальше (комментариев - 11)

Читать статью дальше (комментариев - 11)

| |

|

|

| ПОИСК ПО САЙТУ |

|

|

|

| КАЛЕНДАРЬ | | |

|

| « Октябрь 2025 » |

|---|

| Пн | Вт | Ср | Чт | Пт | Сб | Вс |

|---|

| | 1 | 2 | 3 | 4 | 5 | | 6 | 7 | 8 | 9 | 10 | 11 | 12 | | 13 | 14 | 15 | 16 | 17 | 18 | 19 | | 20 | 21 | 22 | 23 | 24 | 25 | 26 | | 27 | 28 | 29 | 30 | 31 | |

|

| |

| |

|