|

|

Автор: Williams Автор: Williams

Дата: 3 мая 2025 Дата: 3 мая 2025

Просмотров: 274 Просмотров: 274 |

| |

AVEVA PRO/II Simulation 2025

AVEVA PRO/II Simulation optimizes plant performance by improving process design and operational analysis and performing engineering studies. Designed to perform rigorous heat and material balance calculations for a wide range of chemical processes, AVEVA PRO/II Simulation offers a wide variety of thermodynamic models to virtually every industry.

AVEVA PRO/II Simulation offers a comprehensive library of components, thermodynamics and physical property data, and unit operations. Rigorous refinery reactor models now available.

You can create custom models and reporting via Microsoft Excel. AVEVA PRO/II Simulation integrates with industry-standard licensors including HTRI, OLI, Koch-Glitsch, and MySep. Import assay information via Unified Supply Chain Management.

AVEVA PRO/II Simulation can be used in virtually every industry, including oil and gas production, refining, petrochemicals, chemicals, pharmaceuticals, and polymer plant modelling.

AVEVA PRO/II Simulation is available via the cloud in addition to the traditional on-premise access method. This new infrastructure allows for secure user access control, seamless maintenance, and simplified IT overhead. |

| |

Читать статью дальше (комментариев - 3)

Читать статью дальше (комментариев - 3)

| |

|

|

Автор: Williams Автор: Williams

Дата: 6 ноября 2022 Дата: 6 ноября 2022

Просмотров: 1 278 Просмотров: 1 278 |

| |

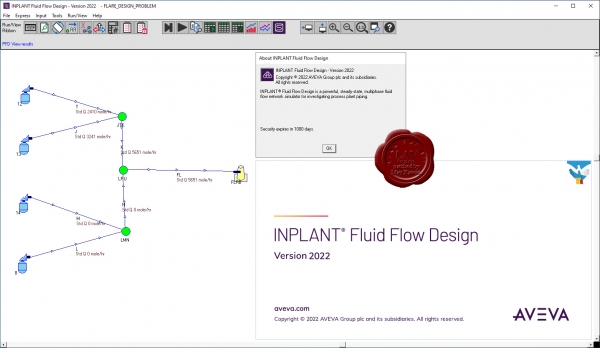

AVEVA (ex. Invensys, SimSci) INPLANT Fluid Flow Design 2022 build 12.10.2022

The INPLANT Fluid Flow Design program is a steady-state, fluid flow simulator for designing, rating, and analyzing plant piping systems. Engineers can quickly rate and analyze the safety of plant piping systems via the INPLANT Fluid Flow Design Graphic User Interface for Microsoft® Windows® Operating Systems. INPLANT Fluid Flow Design also enables the design of new piping systems or the revamp of a wide variety of existing systems. Applications range from simple, single pipe sizing and rating calculations to large, multiphase fluid piping networks with complex, nested-loop topology. Easily solve relief system problems involving networks with single or multiphase fluids at high velocities or in critical flow.

INPLANT - это мощный инструмент моделирования стационарных режимов, проектирования, оценки и анализа трубопроводных систем завода. Инженеры могут быстро оценить и проанализировать безопасность трубопроводов установки с использованием INPLANT. INPLANT также позволяет проектировать новые трубопроводные системы или модернизировать разнообразные существующие трубопроводы. Диапазон применения от поверочного и проектного расчета одной трубы до многофазных кольцевых сетей трубопроводов, со сложной топологией. С помощью INPLANT решаются проблемы однофазных и многофазных систем сброса на факел при высоких скоростях движения флюида или при критических расходах. INPLANT помогает инженерам быстро определить причину плохой гидравлики в работе трубопроводов и способствует формированию экономных решений. |

| |

Читать статью дальше (комментариев - 9)

Читать статью дальше (комментариев - 9)

| |

|

|

Автор: Williams Автор: Williams

Дата: 27 октября 2022 Дата: 27 октября 2022

Просмотров: 1 518 Просмотров: 1 518 |

| |

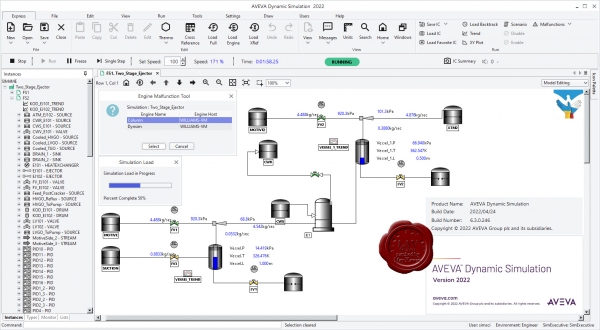

AVEVA (ex. Invensys, SimSci) Dynamic Simulation Suite 2022 build 28.04.2022

AVEVA Dynamic Simulation is a comprehensive, dynamic process simulator that enables users to meet and beat the dynamic challenges of designing, commissioning, controlling, and operating a modern process plant safely, reliably, and profitably.

AVEVA Dynamic Simulation

State-of-the-art, field-proven dynamic simulation for modern process plants.

AVEVA Dynamic Simulation Power

An advanced power plant modeling and dynamic simulation environment for use throughout a power plant’s life cycle.

Engineering Services

An unparalleled combination of industry experience, process simulation knowledge and best-in-class technology.

Operator Training

High fidelity dynamic simulations of the actual process plant connected with 3rd Party control systems as a platform for control checkout and operator training.

By assisting in process design, controls checkout and control system design, AVEVA Dynamic Simulation enables process yield improvement and reduction of capital investment costs.

First principles models, including rigorous thermodynamic and fluid flow calculations, bring a superior level of robustness and accuracy to dynamic process simulation.

Translate a steady-state AVEVA PRO/II Simulation into a running dynamic simulation to eliminate tedious data re-entry, and preserve the thermodynamic methods that you trust.

AVEVA Connect makes AVEVA Dynamic Simulation available via a pure SaaS model in addition to the traditional on-premise access method. |

| |

Читать статью дальше (комментариев - 14)

Читать статью дальше (комментариев - 14)

| |

|

|

Автор: Williams Автор: Williams

Дата: 25 октября 2022 Дата: 25 октября 2022

Просмотров: 1 262 Просмотров: 1 262 |

| |

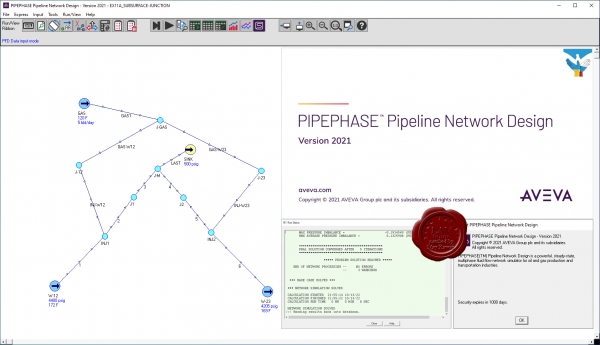

AVEVA (ex. Invensys, SimSci) PIPEPHASE Pipeline Network Design 2021 buid 04.10.2021

Pipeline Network Design can model applications ranging from single well sensitivity analyses of key parameters, to a multi-year planning study for an entire production field. Pipeline Network Design improves profitability and performance in companies across the globe by using proven solution algorithms, modern production methods, and software analysis techniques to create a robust and efficient oil field design and planning tool.

Pipeline Network Design improves profitability and performance in companies across the globe by using proven solution algorithms, modern production methods, and software analysis techniques to create a robust and efficient oil field design and planning tool.

Pipeline Network Design provides a comprehensive set of industry standard empirical and mechanistic methods for analysing multiphase flow phenomena in pipes. Coupled with extensive fluid models and a rigorous energy balance incorporating a detailed heat transfer analysis capability, Pipeline Network Design is a flexible tool for evaluating the complete range of fluid flow phenomena encountered in single-phase and multiphase pipelines.

The time-stepping feature in PIPEPHASE makes it a flexible field planning tool. Once a field-wide network model has been built, the planning tool is created by setting up scenarios for future facility expansion along with reservoir decline characteristics. The completed model provides a unique look-ahead capability for the entire asset, incorporating the long-term effects of both reservoir decline and investment in new facilities.

The robust, field-proven network simulation capability enables the user to model large networks of connected wells, pipes, and associated facilities. The detailed well bore model and extensive inflow performance (IPR) library, combined with a complete set of surface equipment modules, allows you to configure the necessary details of a field-wide oil and gas gathering (or injection) system, and incorporate all of the interdependent components from the sandface to the downstream separation facilities.

Oil producers have a real, quantifiable problem managing and modelling their reservoirs and linking them to the surface. Pipeline Network Design has the modelling capabilities needed to accurately manage and model reservoirs by developing an interface with reservoir simulators and enhancing pipeline technology. |

| |

Читать статью дальше (комментариев - 10)

Читать статью дальше (комментариев - 10)

| |

|

|

Автор: Williams Автор: Williams

Дата: 22 января 2019 Дата: 22 января 2019

Просмотров: 3 166 Просмотров: 3 166 |

| |

AVEVA (ex. Schneider Electric, Invensys) PRO/II Process Engineering v10.2 x64

PRO/II Process Engineering optimises plant performance by improving process design and operational analysis and performing engineering studies. Designed to perform rigorous heat and material balance calculations for a wide range of chemical processes, PRO/II Process Engineering offers a wide variety of thermodynamic models to virtually every industry. PRO/II Process Engineering offers a comprehensive library of components, thermodynamics and physical property data, and unit operations. You can create custom models and reporting via Microsoft Excel. PRO/II Process Engineering integrates with industry-standard licensors including HTRI, OLI, Koch-Glitsch, and Cost Engineering. Import assay information via Unified Supply Chain Management. PRO/II Process Engineering can be used in virtually every industry, including oil and gas production, refining, petrochemicals, chemicals, pharmaceuticals, and polymer plant modelling. PRO/II Process Engineering is available via the cloud in addition to the traditional on-premise access method. This new infrastructure allows for secure user access control, seamless maintenance, and simplified IT overhead. |

| |

Читать статью дальше (комментариев - 11)

Читать статью дальше (комментариев - 11)

| |

|

|

Автор: Williams Автор: Williams

Дата: 11 ноября 2013 Дата: 11 ноября 2013

Просмотров: 1 297 Просмотров: 1 297 |

| |

Invensys SimSci-Esscor HEXTRAN v9.2

HEXTRAN - программное решение для моделирования теплообменных процессов, предназначенное для быстрой оценки сложных проектных, операционных и модернизационных задач. HEXTRAN в среде SIM4ME является ядром моделирования теплообменных процессов среди продуктов SimSci. HEXTRAN оснащен графическим пользовательским интерфейсом на основе Java с системой справки HTML, которая поддерживает создание спецификации теплообменника по стандарту TEMA в форматах HTML и Excel. Усовершенствованные возможности отображения результатов включают графики и дисплеи, позволяют проводить глубокий анализ результирующих кривых теплообмена по зонам. HEXTRAN обеспечивает повышенную эффективность для всех типов работ по проектированию и оперативному анализу, например, проектирование индивидуального теплообменника и сети, пинч-анализ, зональный анализ, разделение потока, расчет и анализ коэффициентов теплоотдачи и теплопередачи и оптимизации цикла очистки.

Подробнее тут. |

| |

Читать статью дальше (комментариев - 8)

Читать статью дальше (комментариев - 8)

| |

|

|

| ПОИСК ПО САЙТУ |

|

|

|

| КАЛЕНДАРЬ | | |

|

| « Июль 2025 » |

|---|

| Пн | Вт | Ср | Чт | Пт | Сб | Вс |

|---|

| | 1 | 2 | 3 | 4 | 5 | 6 | | 7 | 8 | 9 | 10 | 11 | 12 | 13 | | 14 | 15 | 16 | 17 | 18 | 19 | 20 | | 21 | 22 | 23 | 24 | 25 | 26 | 27 | | 28 | 29 | 30 | 31 | |

|

| |

| |

|