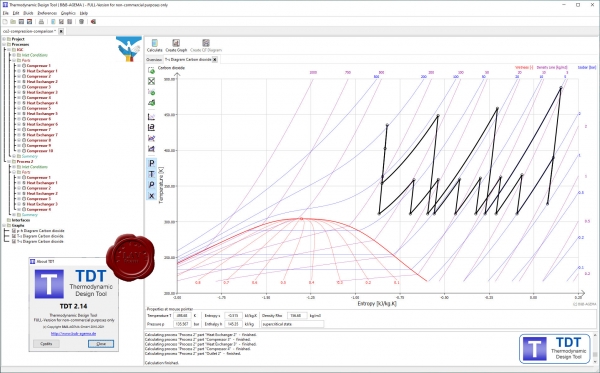

B&B-AGEMA Thermodynamic Design Tool 2021 v2.14

The TDT-software (Thermodynamic Design Tool) is an easy to use and efficient tool for analyzing, designing and dimensioning of thermodynamic processes.

It comprises process media based on NIST Refprop (there are more than 100 fluids and numerous mixtures available; such as air, water/steam, CO2, hydrogen, common alkanes and refrigerants or mixtures composed of them), whose change in state is calculated taking into account real gas effects. The thermodynamic process sequences can be visualized and scaled by common diagrams (e.g. h-s, T-s, p-T) and calculated values are precisely listed in tables.

TDT supplies to the user an easy and interactive graphical user interface and a huge number of options for setting up the thermodynamic process according to the individual requirements. Predefined turbomachinery components such as compressor/pump, combustion chamber, turbine, condenser and heat exchanger form basic elements and can be extended by additional process branches and/or loss correlations. Depending on the components, only few input values such as efficiency, outlet pressure or pressure ratio, heat or temperature change as well as pressure or mass losses are necessary to configure the single elements.

As an example, TDT has been used for optimization of a multi-stage inter-cooled compression process of CO2 for a power plant concept with Carbon Capture & Storage (CCS) technology.

TDT is continuously further developed by B&B-AGEMA and has been applied in a huge number of industrial projects.